TERRASYSTEM Size 1 and 2

Whether on rail routes, at airports or in energy networks, the availability of modern systems largely depends on reliable power supply and transmission of information. In this context it is important that a multitude of sensitive cables are efficiently protected against outside influences by means of cost-effective measures that feature flexibility in implementation and allow modifications and extensions to be carried out fast and easy.

Quick and easy to install

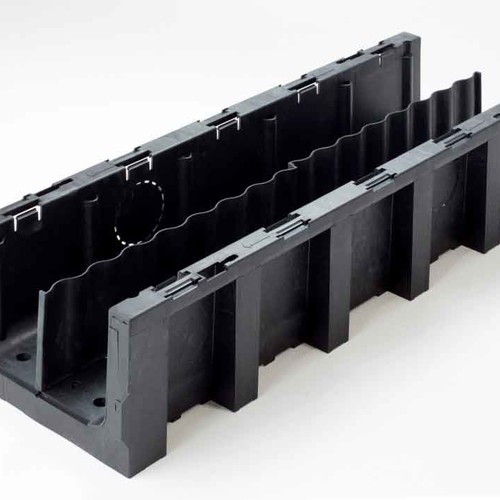

The use of lightweight plastics provides a multitude of advantages, ranging from cost-effective transport through simplified installation on site without the need for any transport and hoisting tools, to new application options. Rupture joints for cable outlets allow a more efficient installation. Thanks to trough wall aprons, no hollow spaces are created during the sealing process and transverse drainage is ensured.

Flexible in use and resuable

The lid element of the plastic duct, which is walkable and is lockable, can be easily opened. This allows a fast control or reinstallation of the cables. Furthermore, the plastic cable duct can be easily removed and reused, and hence offers the perfect concept for solutions for limited periods. Overall, the plastic cable duct presents a commercially viable alternative to conventional concrete cable ducts. Thanks to this solution, the project duration is shorte- ned, construction and labour costs are reduced, and high disposal costs are avoided as a result of the 100 % recycling capability.

Robust and lightweight

The plastic cable duct is light in weight and, thanks to its integrated columns and ribs, extremely solid. It is able to withstand the same loads as a concrete duct. The lid is walkable and can be closed and opened as many times as desired, allowing convenient laying and fast inspection.

Convenient and universal

Preset mitre lines allow that the plastic cable duct can be adapted easy and individual to all on-site condi- tions, such as curves, T-pieces and angles.

Simple and flexible handling

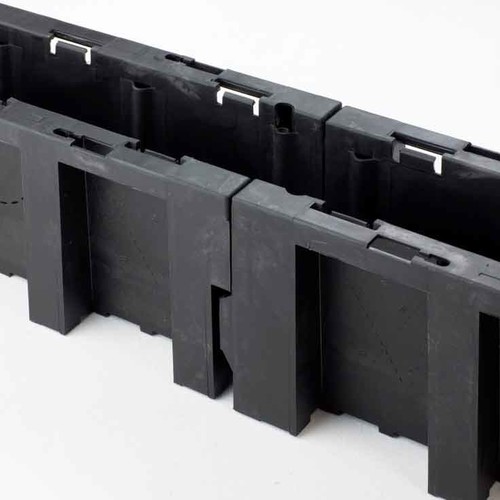

Plastic cable ducts can be installed by hand fast and easy. They are simply plugged in one to another, without any supplementary parts being required. Furthermore, thanks to the lightweight construction of these ducts, large quantities can be transported and unloaded cost-effective without heavy lifting tools.

Quick and safe installation

Preset cutouts for cable penetrations ensure fast and simple handling.

- fast and efficient transport fast and easy unloading easy to install by hand

- flexible adaption of the elements on site (cutting lives 15°/30° integrated in the duct)

- environmentally compatible and fully recyclable polypropylene lightweight construction 4.5 kg for TERRASYSTEM Size 1

- and 8.4 kg for TERRASYSTEM Size 2

Ground mounted Cable Duct System in PP

The use of lightweight plastics have a multitude of advantages, these range from cost-effective transport through simplified installation on site without the need for any transport and hoisting tools, to new application options. Rupture joints for cable outlets allow a more efficient installation. Thanks to through wall aprons, no hollow spaces are created during the sealing process and transverse drainage is ensured.

The plastic cable duct is light in weight and because of list integrated columns and ribs, extremely solid. Preset mitre lines allow that the plastic cable duct can be adopted easily and individually to all on-site conditions.

The lid element of the plastic duct, which is walkable and is lockable, can be accessible. This allows for modification or reinstallation of the cables. Furthermore, the plastic cable duct can be easily removed and reused, and hence offers the perfect solution for a variety of time periods.

Thanks to this solution, project durations are shortened, construction and labour costs are reduced, and high disposal costs are avoided as a result of the 100% recycling capability.

Technical Data

Material

Polypropylene:

- UV-stabilized

- halogen free

- fully recyclable

- not hazardous to the environment

Mechanical Values

Load capability is approx. 10 kN without rupture.

Electrical Characteristics

The electric strength in accordance with DIN VDE 303-21 is 670 kV/cm. Earthing and insulated construction are not required. Surface resistance is approx. 1000 Ohm. DIN IEC 93/VDE 0303, Part 30.

Thermal Characteristics

Permanent thermal stability is ensured at outside temperatures of -30°C to +85°C.

Fire Characteristics

K1 in accordance with DIN 53438 part 2 Halogenfree in accordance with IEC 61249-2-21

Weight

TERRASYSTEM Size 1: approx. 4.5 kg/metre duct and lid

TERRASYSTEM Size 2: approx. 8.4 kg/metre duct and lid